Wellhead Isolation: Safety and Environmental Protection in Oil & Gas

Oil and gas operations must protect workers and the environment from potential exposure to hazardous substances throughout the operation. Safety and environmental protection are good practices, and they’re also highly regulated in most jurisdictions.

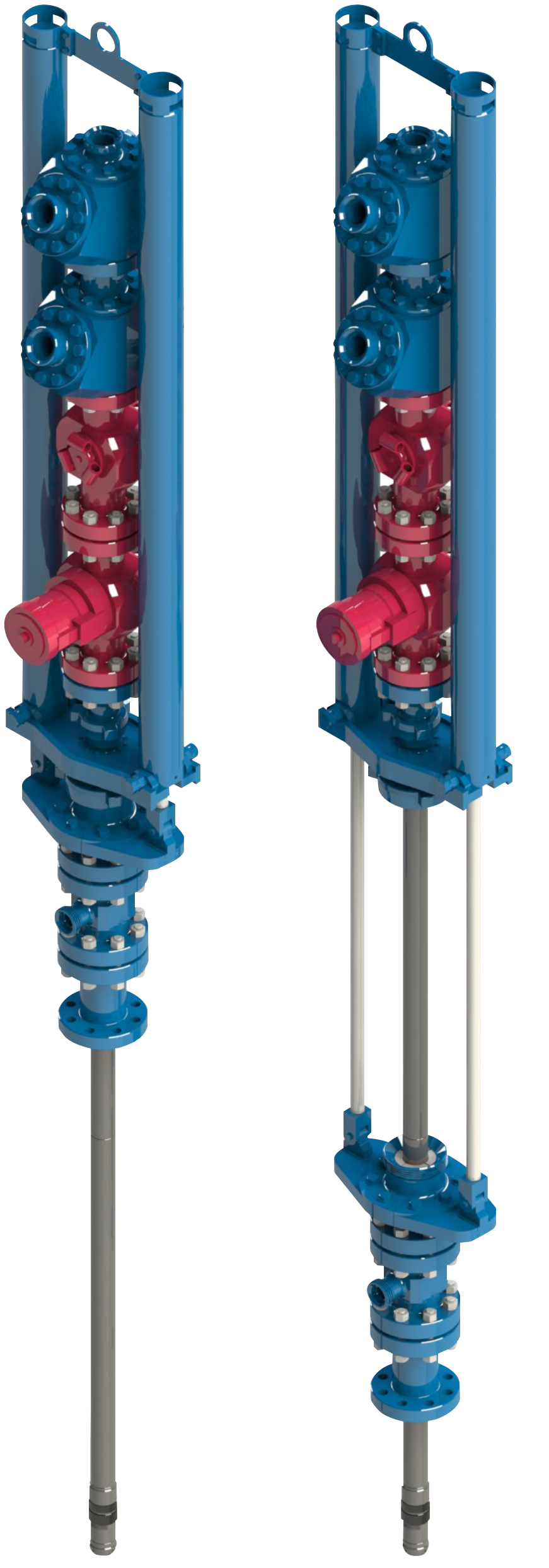

Wellhead isolation is the practice of safeguarding oil and gas wellheads during operation and maintenance. Operations in the oil and gas industry use a

wellhead isolation tool to create a barrier that protects those operating the machinery while also preventing spills that may harm the environment.

Keep reading to learn more about how wellhead isolation equipment is crucial for any oil and gas operation.

What is Wellhead Isolation?

Wellhead isolation is a crucial process throughout the oil and gas industry. Specialized equipment safeguards wellheads during drill, completion, or intervention operations.

The overall procedure involves isolating the wellhead oil and gas from high-pressure zones using isolation tools or valves. This barrier between the wellhead and the high-pressure area protects the wellhead components from damage or failure due to extreme pressures.

Wellhead isolation is crucial for ensuring worker safety, preventing environmental hazards, and operational integrity. The result is safe, controlled access to wellbores that benefit oil and gas operations globally.

Importance of Safety and Environmental Protection in Oil & Gas

The oil and gas industry deals with high pressures and hazardous materials, with any failure of equipment or safety processes leading to extensive environmental damage or loss of life.

As such, it’s vital for operations to implement robust safety measures to protect from spills, emissions, and ecological damage. Oil and gas organizations must meet strict compliance requirements concerning safety to protect both workers and the environment. Using a specialized oil well head isolation tool contributes significantly to these goals.

Understanding Wellhead Isolation

Wellhead isolation equipment is critical for protecting the environment and workers alike. The process of isolating the wellhead provides safety during drilling, maintenance, or completion. So, let’s explore how wellhead isolation works before so we can see how it impacts safety.

Components of a Wellhead

Oil gas and oil wellheads are a vital component of any drilling or completion operation. While there are a range of specific wellheads out there, they all share a few similarities. A wellhead consists of several key components, which are:

- The casing head secures the end of the casing strings

- Tubing head for supporting tubing strings

- Valves for flow control

- A variety of seals and connectors that ensure pressure integrity

The wellhead is essential, and the wellhead isolation tool grew out of necessity to safeguard other equipment, employees, and the environment.

Purpose of Wellhead Isolation

Isolation equipment services and tools all focus on specialized equipment for wellhead isolation. The purpose of wellhead isolation is to protect the wellhead from the extreme pressures encountered during fracture, well servicing, drilling, or other common operations.

Protecting the wellhead guards against equipment failure, as even durable wellheads may not be equipped to handle unexpected changes in force and pressure. Using a

wellhead isolation tool provides a much better layer of protection for people, equipment, and the environment.

Types of Wellhead Isolation Techniques

There is a wide variety of wellhead isolation techniques designed to accommodate varying types of oil and gas operations. The application and specific design may vary, but the tools will include slip seals, packers, and mechanical isolation tools designed to manage pressure levels and wellbore conditions.

Safety Implications of Wellhead Isolation

How does the wellhead provide additional safety for workers? Creating an additional barrier creates significant safety benefits for those working throughout the operation. Let’s break down a few of the ways safety is enhanced by wellhead isolation.

Preventing Blowouts and Uncontrolled Releases

Wellhead isolation securely seals the wellhead, manages pressures, and prevents everything from minor uncontrolled releases to catastrophic events. Without using this tool and associated best practices, employees may be exposed to hazardous and flammable materials.

Protecting Workers and Equipment

Controlling well pressures creates a secure barrier that minimizes the risk of failure and the likelihood of accidents. Wellhead isolation tools and best practices provide the utmost level of control over wellbore pressures, which can often be unpredictable and change from moment to moment.

Ensuring Safe Drilling and Production Operations

Using a durable wellhead isolation tool ensures that the high pressures and other everyday challenges associated with extraction do not compromise the wellhead’s integrity. As such, wellhead isolation facilitates safe and efficient operations while meeting or exceeding strict safety standards.

Environmental Benefits of Wellhead Isolation

Protecting the environment is a vital aspect of any oil and gas operation. Wellhead isolation equipment and best practices strive to prevent spills, contamination, and preserve biodiversity. Let’s break down each of these elements and explore how wellhead isolation tools help.

Minimizing Spills and Leaks

One key benefit of using wellhead isolation tools and best practices is minimizing situations that may expose the surrounding environment to harmful substances. A wellhead isolation tool secures the seal and effectively controls the fluids being extracted or used in other operations. As a result, the risk of releasing oil and gas into the surrounding environment is significantly reduced.

Reducing Contamination of Groundwater and Surface Water

A primary concern with oil and gas operations is contaminating groundwater or surface water should accidents occur. The isolation tool and best practices prevent chemicals, hydrocarbons, and other pollutants from escaping the wellbore. Otherwise, spills can jeopardize public health by affecting local drinking water.

Preserving Ecosystems and Biodiversity

Implementing wellhead isolation processes goes far in helping preserve the local ecosystem and biodiversity. You’ll prevent contaminating local plants and habitats on the site of the extraction or process operation, which may otherwise occur with an oil, gas, or natural gas well.

Challenges and Solutions in Wellhead Isolation

Implementing an effective oil and gas well head isolation tool can have some challenges to understand and overcome. You need to begin understanding the most extreme possible pressures, safeguard against corrosive environments and train personnel for precise installation.

The solution is to plan meticulously, choose the right wellhead isolation tool, and plan all personnel involved in the wellhead operation. Additionally, abide by common best practices that focus on maintenance, continuous maintenance, and maintaining your compliance standings.

Future Trends in Wellhead Isolation

What might the future hold for wellhead isolation tools and best practices? Some of the key ways we see the future affecting this industry include:

- Technological advancements and innovations: We expect to see the ongoing advancements of embedded sensors, AI, and material sciences to make wellhead isolation tools more effective and responsive than ever before.

- Regulatory changes and industry standards: Compliance and regulatory legislation rarely sit still. Gas wellhead isolation tools need to evolve to keep your operation compliant.

- Sustainability and environmental considerations: The growing emphasis on sustainable practices and environmental protection demands reliable and effective isolation practices to avoid possible harm.

The Integral Role of Wellhead Isolation in the Oil & Gas Industry

Wellhead isolation is critical to the ongoing success of any extraction or processing operation throughout the oil and gas industry. These specialized tools and processes protect workers and the environment from the potential harm of oil and gas wells.

Advancements in manufacturing technologies and possibly breakthroughs in construction materials will undoubtedly benefit the future of wellhead isolation. You need to ensure your isolation tool is ready to meet the demands of your operation now and in the future.

GN Corporations is a leading provider of specialized equipment, and we’ve helped oil and gas companies enhance their operations with durable wellhead isolation tools. Ready to discover how we can help your organization?

Learn more about our wellhead isolation tools and custom services today.