Vertically-integrated Solutions

Manufacturing services

Our manufacturing services offer versatility, scalability, and cost-effective solutions

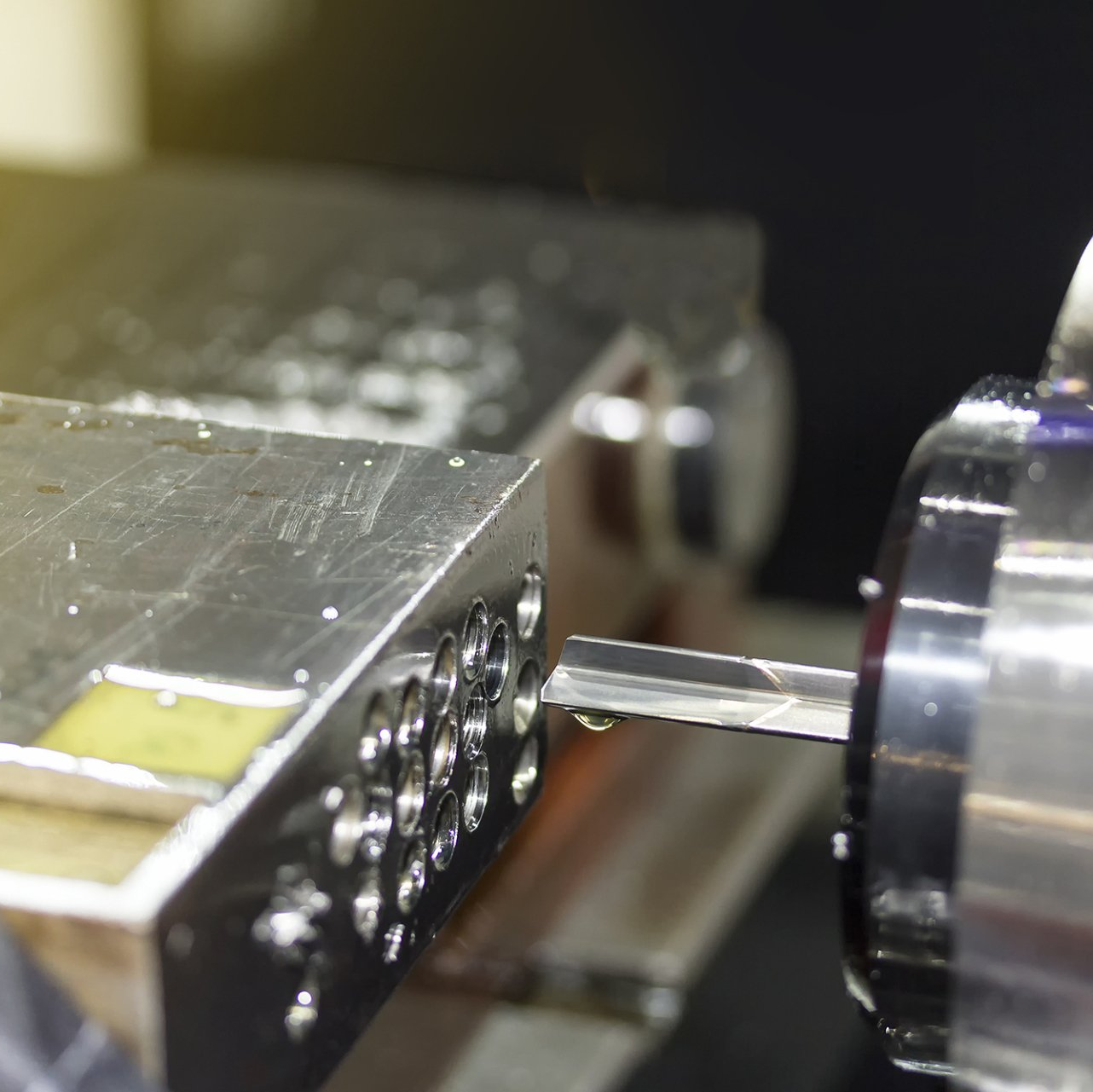

CNC MACHINING

Design, develop, and manufacture complex metal components with our GN 4.0-ready advanced CNC machining solutions. From boring, cutting, drilling, to turning tools—we are your complete manufacturing technology solution.

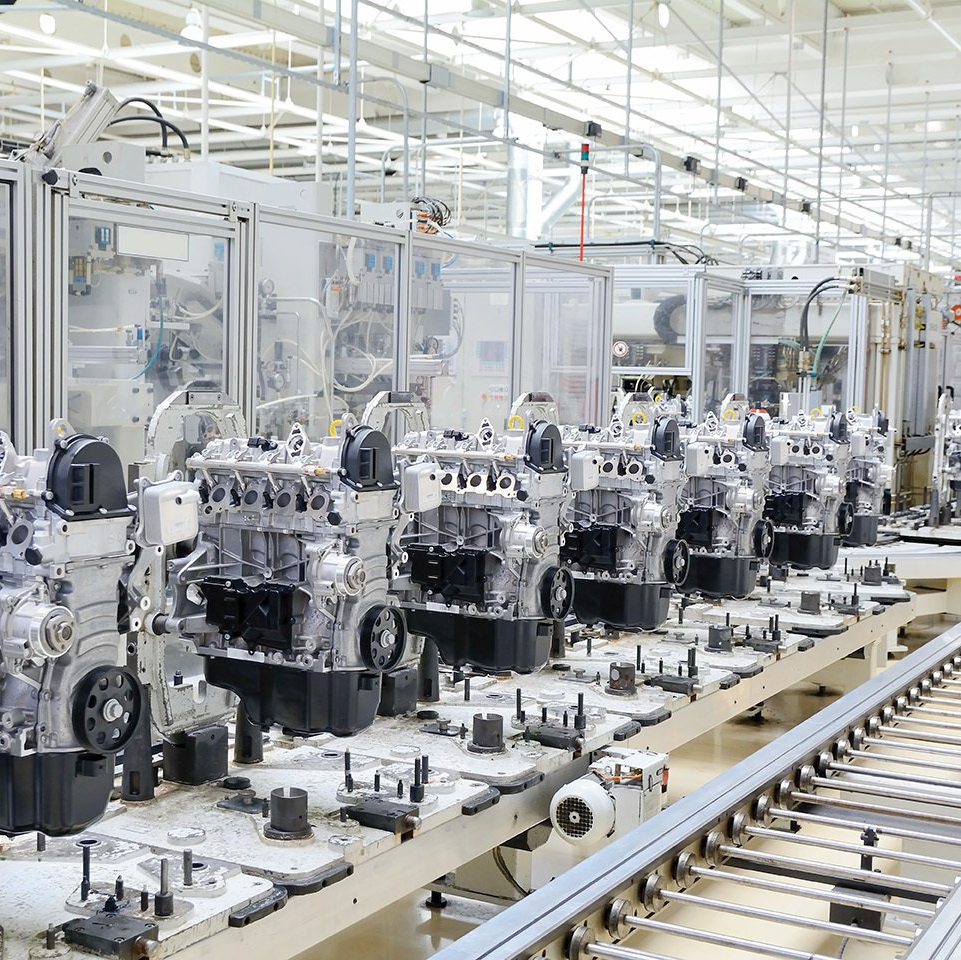

ASSEMBLY

Ensuring fit, form, and function by completing the manufacturing process with final assembly.

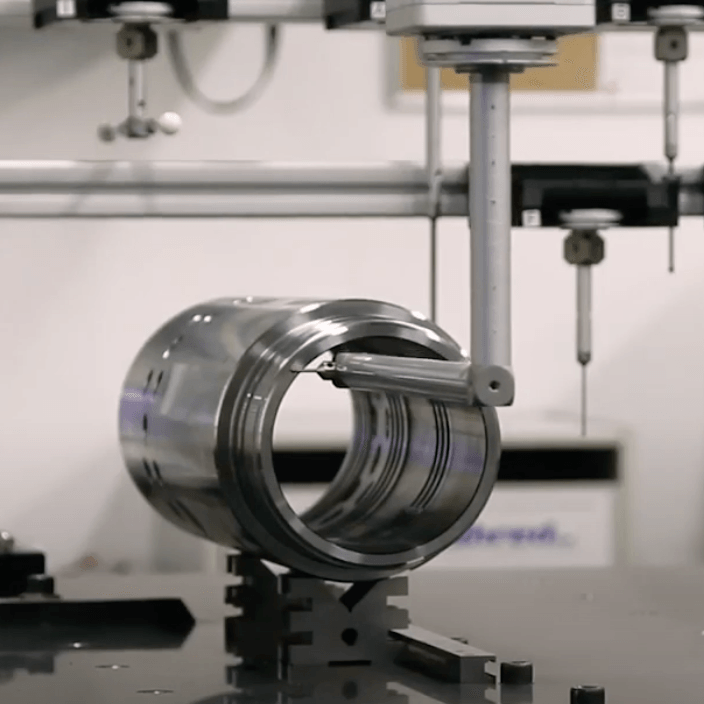

QUALITY ASSURANCE

Guarantee complete quality assurance with advanced machine tool probing, 7-axis scanning technology, and advanced coordinate measuring machines.

WATERJET CUTTING

Fabricate the complex parts your machines need without compromising their structural integrity. Our hyper-accurate water jet drilling service is versatile and our water jet drilling devices capable of cutting metal, stone, glass, wood, and rubber.

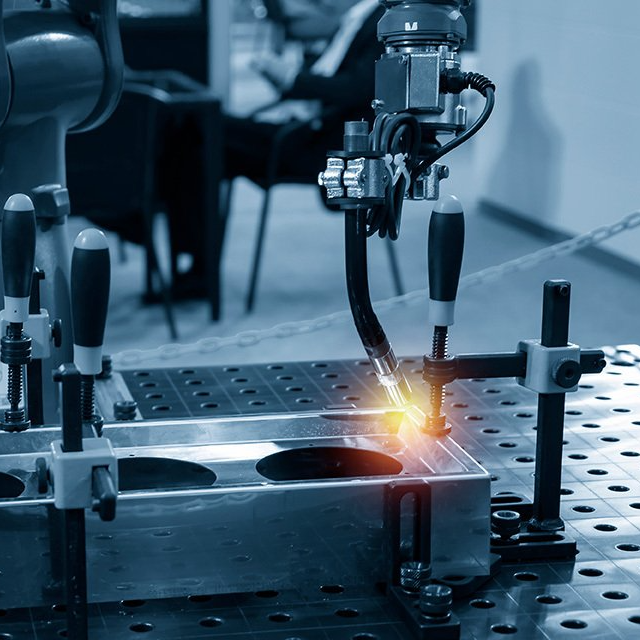

WELDING, BRAZING, HARDFACING

Our welding capabilities are based on our attention to detail, technical knowledge, and industry accreditation.

GN POLYMERS INC.

Our world-class polymer division leverages industry-leading machines and technology, and is backed by experienced, qualified scientists. Materials include rubber, virgin peek, and other elastomer materials, and products include:

- Compression molding

- Preforming

- 2-roll mill

PAINTING

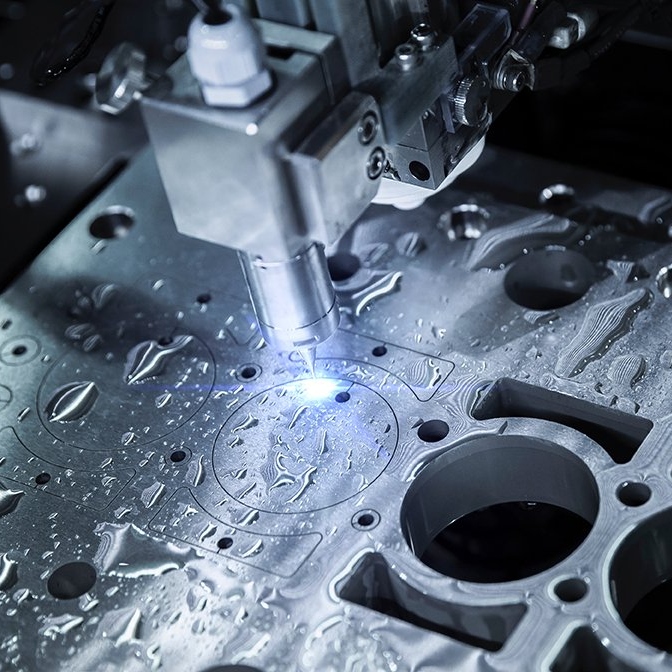

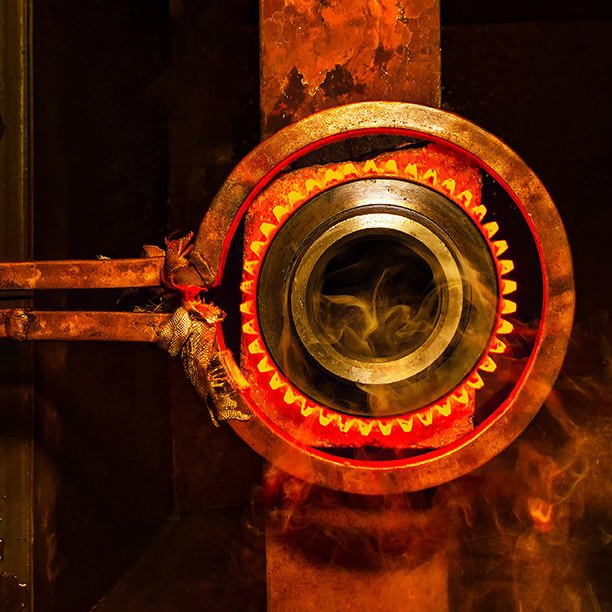

INDUCTION

HARDENING

Boost the performance and longevity of your stainless steel components. Our induction hardening service expedites the heating and hardening process, providing you with the consistent results you need.

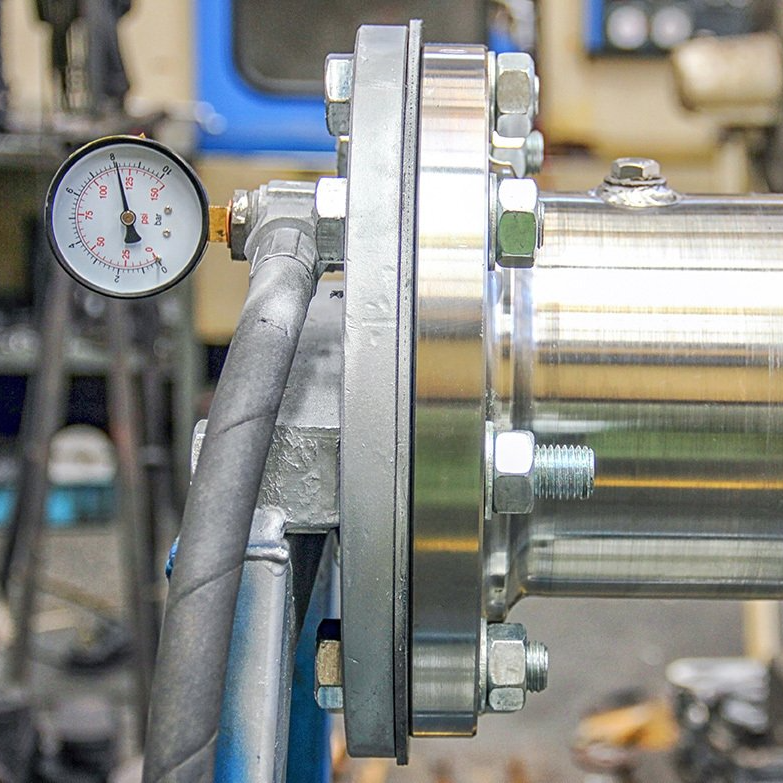

PRESSURE

TESTING

Ensure your piping and equipment are leak proof and up to the task. Our pressure testing pinpoints weaknesses, potential leaks, and other issues that could impact the performance of the equipment oil & gas, automotive, and other leading industries rely on in the field.

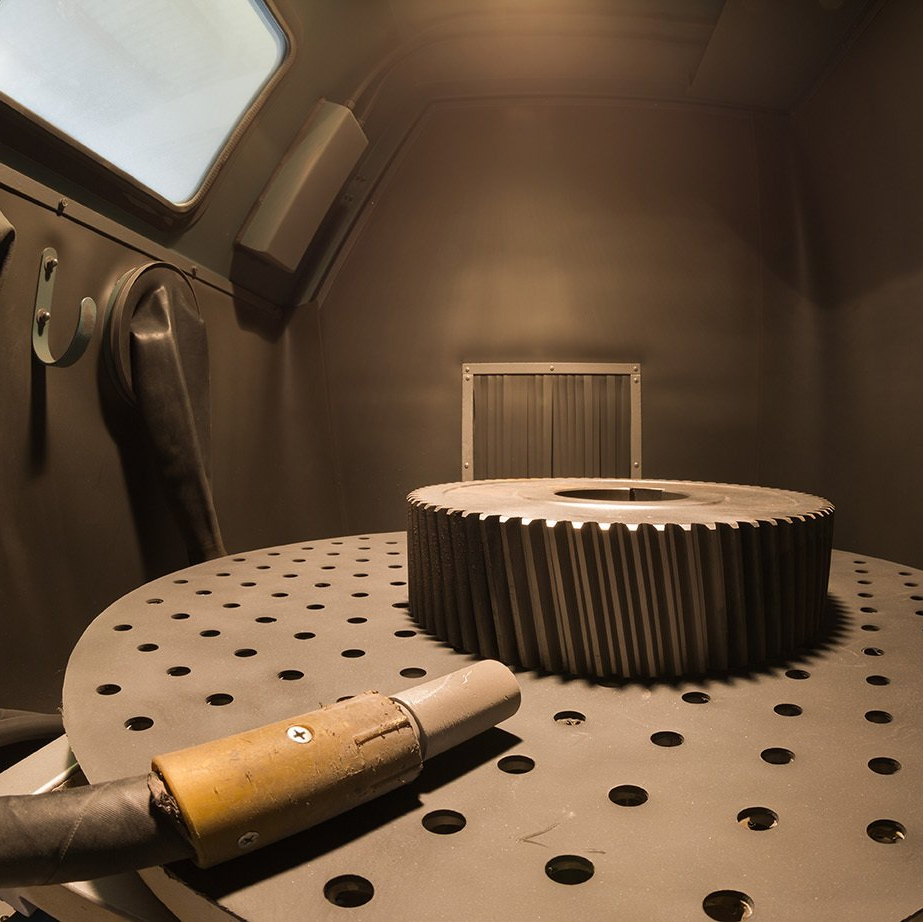

SAND BLASTING

Remove residue with optimal precision and improve the final quality of your finished product.

SPEAK TO A MANUFACTURING SPECIALIST

Have questions or a complex project in mind?

Talk to one of our manufacturing specialists and find out how our advanced solutions can be tailored to your industry needs.

Contact Us

GN Manufacturing Services FAQS

What manufacturing services does GN Corporations offer?

GN Corporations provides a comprehensive suite of advanced manufacturing solutions, including precision CNC machining, efficient assembly manufacturing, and smart factory solutions. We serve a wide range of industries such as aerospace, automotive, defense, oil & gas, and technology.

How does GN Corporations ensure precision and quality in its CNC machining services?

We utilize state-of-the-art CNC machinery and follow rigorous quality control standards to guarantee high precision on every project. Our experienced technicians employ advanced measurement tools and strict process protocols to ensure consistent, high-quality outputs.

Which industries do you serve, and how do you address complex manufacturing requirements?

Our services are tailored for industries including aerospace, automotive, defense, oil & gas, and technology. By integrating advanced manufacturing techniques, customized solutions, and industry best practices, we meet the unique and often complex requirements of our diverse client base—from prototyping to full-scale production.

How do your smart factory solutions improve production efficiency?

Our smart factory solutions leverage the latest in digital technology, including IoT integration and data analytics, to streamline manufacturing processes. This approach reduces downtime, optimizes workflow, and increases overall productivity, allowing your operations to run more efficiently and cost-effectively.

What is the typical turnaround time for manufacturing projects?

Turnaround time can vary based on the project’s complexity and volume. However, we pride ourselves on efficient production cycles through optimized processes and dedicated project management. For a detailed timeline tailored to your specific needs, please contact our team for a personalized consultation.