Destructive vs. Non-Destructive Testing: What You Need to Know

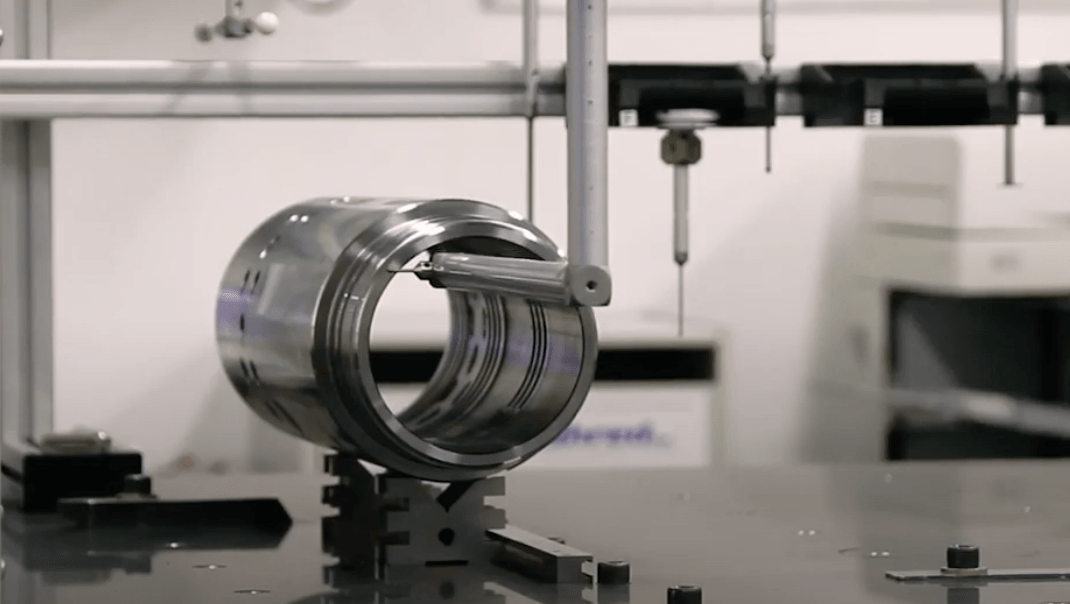

Non-destructive testing, also known as NDT, is a term used to describe a variety of inspection techniques that allow for inspectors to collect necessary data about a specific material without having to damage the material itself. This umbrella term encapsulates several specific non-destructive inspection methods and tools that inspectors rely on. Among other NDT testing solutions used in the industry, Magnetic Particle Inspection (MPI) and Liquid Penetrant Inspection (LPI) have proven to be very effective.

Common Methods of Non-Destructive Testing

- MPI: This is designed to detect flaws on or near the surface of ferromagnetic substances. It is an effective method to identify any minor cracks, holes, cold lap, or insufficient sidewall fusion in magnetic material. The ideal MPI technique utilizes a 110v AC hand-held electromagnetic yoke magnet in conjunction with a removable paint as a background color and iron powder mixed into a liquid carrier to produce a magnetic ink. As the surface is magnetized, the iron particles will produce a deformed magnetic field pattern around the defective area. This NDT method offers excellent resolution for defects in a variety of magnetic materials, castings, and stress-bearing items that can form fatigue cracks.

- LPI: With LPI, surface defects on nonporous materials can be detected, including hairline cracks, leaks, porosity, and fatigue cracks on casting, forging, and welding surfaces. The penetrating liquid can be applied by submerging, spray coating, or brushing, and after the penetrant is given the appropriate time, the excess is removed to add a developer. This draws out the remaining penetrant from the defects to expose them under white or ultraviolet light, depending on the dye used.

Advantages of MPI

- Detects surface and near-surface defects

- Can be a portable and low-cost solution

- Results can be achieved immediately

- Defects can be easily scene directly on the surface of the material

- Previously hidden defects are detectable

- Irregularly shaped components can be inspected

Disadvantages of MPI

- The material subjected to testing must be ferromagnetic

- In many cases, paint coats must be removed prior to the procedure

- Post-procedure cleaning and demagnetization of the component is necessary

- Subsurface sensitivity is usually 0.1-inch but can be deeper in more ideal conditions

- Magnetic field lines must be aligned with the defect

Advantages of LPI

- Large surface areas and large volumes can be inspected quickly and cost-effectively

- LPI can handle parts with complex geometric shapes

- Defects are seen directly on the component

Disadvantages of LPI

- Can only identify defects that have broken through the surface

- Precise surface cleaning and preparation are vital to the process

- The surface must be smooth and nonporous

- Upon completion, a thorough cleaning is necessary to remove the residual inspection material

- The procedure requires several operations under meticulously controlled conditions

- Knowledge of proper chemical handling precautions is essential

The NDT methods can ensure that after parts are machined, they endure. Both MPI and LPI can detect developing issues as parts undergo usage stressors that can affect structural integrity and performance.

The other category of inspection techniques is destructive testing. This term describes any type of inspection method or tool that has to destroy or otherwise interfere with the specific part in order to inspect it. For example, some industries, such as aerospace testing, can be used to determine the physical properties of components.

Today, we’re going to examine the differences between non-destructive and destructive testing. Before we can dive into NDT testing, we must first learn about destructive testing.

Common Methods of Destructive Testing

Any tests that will alter, damage, or destroy the material that is being inspected is considered a destructive testing method. Some of the common examples of destructive testing are:

- Three-point bend testing: This technique calls for examining the flexibility and durability of a specific material by bending in at three points to create a specific angle.

- Tensile testing: This method is also known as tension testing and calls for applying controlled tension to the material and documenting how it reacts. This might be used to determine a materials failure point or ascertain the maximum load amount.

- Macro sectioning: This type of weld testing will take a given material and alter it with polishing and etching to examine it.

The above list is not an all-encompassing list, but it is helpful in conceptualizing why destructive testing might be used.

Codes and Standards For Non Destructive Testing

NDT inspection techniques are used for many different kinds of inspections. These techniques are typically used with materials or objects that can become dangerous when altered, such as a boiler or pressure vessel.

Due to the sensitive nature of the types of materials and products that call for NDT, several different standards and codes have arisen to guide these processes. Most countries have laws that require companies within these industries to abide by the regulatory guidelines, and for technicians to have a certain level of certification when conducting NDT.

Assets that present a high risk must be inspected by a certified inspector, handles by an experienced technician, and also be approved by a certified witness from the regulatory body. Some of the most commonly followed NDT standards organizations are:

- API (American Petroleum Institute)

- ASME (American Society for Mechanical Engineers)

- ASTM (American Society for Testing and Materials)

- ASNT (American Society For Nondestructive Testing)

- COFREND (French Committee for Non-destructive Testing Studies)

Any organization that makes use of NDT testing must ensure that they abide by the correct set of codes and standards, otherwise, they risk incurring fees.

Should You Use NDT Testing? We Can Help You Decide

Any facility or organization that deals with materials or assets that may create a dangerous situation if altered should make use of NDT testing. For example, oil refineries should ensure they are following the appropriate NDT oil and gas standards and use the appropriate non-destructive testing techniques to ensure a safe inspection process.

If your business wishes to ensure the safety of all employees, you must ensure that NDT practices are used with any dangerous materials.

Are you looking for a tier-1 manufacturer that can help you with your NDT testing needs?

Get in touch with GN today to learn more.